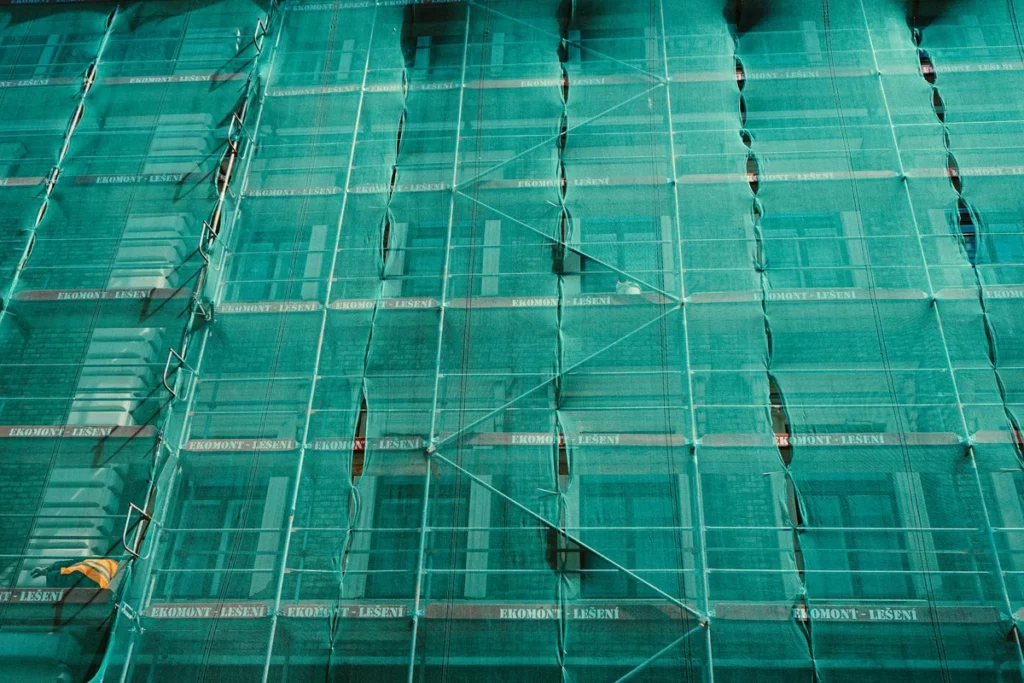

What are Scaffold Mesh and Scaffold Netting?

Construction site safety requires strong protective materials to keep workers and the public safe. Two important safety features in modern construction are scaffold mesh and scaffold netting.

What is Scaffold Mesh?

Scaffold mesh is a heavy-duty, woven material designed to provide comprehensive protection against weather elements and debris. Made from durable polyethylene, it creates a solid barrier that shields construction activities from wind, rain, and UV rays while containing dust and small particles within the work zone.

The choice between scaffold mesh and scaffolding netting shapes the safety and efficiency of your construction project. Each material serves distinct purposes – scaffold mesh excels in weather protection and debris containment, while netting prioritises fall prevention and worker safety.

What is Scaffold Netting?

Scaffold netting, on the other hand, is a lighter, more flexible material crafted from high-density polyethylene (HDPE). Its main purpose is to catch falling objects and prevent workers from accidental falls, acting as an essential safety net during construction operations.

These safety materials are crucial on Australian construction sites:

- Protection of workers from falls and falling objects

- Containment of construction debris

- Weather protection for ongoing work

- Dust control in urban areas

- Compliance with workplace safety regulations

The Australian construction industry’s commitment to safety has made these materials standard requirements on building sites. Their proper use helps prevent accidents, protect pedestrians, and maintain efficient work processes while meeting strict safety standards set by regulatory bodies.

Read more at: Plywood Formwork Tips for Stronger, Smoother Concrete Finishes

How Does Scaffold Netting Work?

Scaffold netting serves as a critical safety barrier on construction sites, catching falling debris and protecting workers from potential hazards. This lightweight, high-tensile mesh creates a protective envelope around scaffolding structures.

Installation Methods:

- Vertical attachment using cable ties or bungee cords

- Horizontal placement for overhead protection

- Secure fixing at regular intervals (typically every 1-2 metres)

- Double-layered installation for enhanced safety

The netting’s design incorporates specific features for maximum effectiveness:

- Small mesh apertures (typically 2-4mm) to catch minute debris

- UV-stabilised materials for weather resistance

- Fire-retardant properties meeting BS EN standards

- High visibility options for improved site safety. Read more about resistance on https://www.bcm.edu/departments/molecular-virology-and-microbiology/emerging-infections-and-biodefense/antibiotic-resistance

OSHA Compliance Requirements:

- Minimum breaking strength of 100 pounds (45kg)

- Regular inspection and maintenance protocols

- Proper overlap between sections (minimum 150mm)

- Secure attachment to scaffold framework

The netting’s flexibility allows it to absorb impact without tearing, making it ideal for:

- Multi-storey construction projects

- Renovation works

- Building maintenance

- Demolition sites

Proper tensioning during installation ensures optimal performance, with the netting remaining taut enough to catch debris yet flexible enough to prevent structural stress on the scaffolding system.

What Are the Characteristics of Scaffold Mesh?

Scaffold mesh stands out with its robust polyethylene material construction, designed specifically for construction site protection. The dense weave pattern creates a solid barrier that effectively blocks debris while allowing air circulation.

Key Physical Properties:

- High-density polyethylene composition

- UV-stabilised material for extended outdoor use

- Tear-resistant reinforced edges

- Wind permeability rating of 50-70%

- Weight: 230-280g/m²

The weather protection capabilities of scaffold mesh make it invaluable for construction projects. It shields work areas from:

- Rain and snow

- Strong winds

- Direct sunlight

- Dust particles

Colour Options and Their Applications:

- Green: Blends with surrounding vegetation, ideal for residential areas

- Black: Maximum sun protection, reduces glare

- White: Enhances natural light penetration

- Blue: High visibility, commonly used in commercial construction

The mesh’s durability allows for multiple project uses, with a typical lifespan of 12-24 months under normal weather conditions. Its fire-retardant properties meet Australian safety standards AS 4389, making it suitable for high-risk construction environments. Click here to find more about durability.

The material’s strength-to-weight ratio enables easy installation while maintaining structural integrity. A single sheet can cover substantial areas, reducing installation time and labour costs.

What Are the Key Differences Between Scaffold Mesh and Scaffold Netting?

Scaffold mesh and netting serve distinct purposes on construction sites, with key differences in their material composition and practical applications.

1. Material Composition

- Scaffold mesh: Heavy-duty polyethylene or polypropylene material with reinforced edges

- Scaffold netting: Lightweight knitted polyethylene with smaller mesh openings

2. Design Features

- Scaffold mesh:Rigid structure with enhanced tear resistance

- UV-stabilised coating for extended outdoor use

- Reinforced eyelets every 50cm for secure fixing

- Scaffold netting:Flexible, lightweight construction

- High tensile strength despite minimal weight

- Debris-catching capabilities

3. Protection Focus

- Scaffold mesh prioritises:Weather protection (wind, rain, sun)

- Site security

- Dust containment

- Scaffold netting emphasises:Fall prevention

- Debris containment

- Worker safety

4. Selection Criteria

- Project duration: Mesh for long-term, netting for shorter projects

- Weather exposure: High-wind areas benefit from mesh’s rigidity

- Safety requirements: Netting excels in fall protection

- Cost considerations: Netting typically offers more economical solutions

- Site location: Urban areas might require mesh’s enhanced dust control

These distinct characteristics make each option suitable for specific project requirements, with safety standards and environmental conditions playing crucial roles in the selection process.

How to Choose the Right Scaffold Material for Your Project

Selecting the appropriate scaffold material requires careful consideration of three critical factors: safety, visibility, and durability.

1. Safety Requirements

- Check weight capacity ratings for your specific project needs

- Assess fire-resistance properties of materials

- Verify compliance with local building codes and OSHA standards

- Consider weather conditions and environmental factors

2. Visibility Considerations

- Light-coloured materials enhance natural illumination

- Mesh density affects sight lines for workers

- High-visibility options improve public safety near construction zones

- Clear signage visibility through the material

3. Durability Factors

- UV resistance for extended outdoor exposure

- Tear and puncture resistance ratings

- Weather resistance capabilities

- Expected lifespan under project conditions

Your project’s specific requirements will guide material selection. High-rise construction projects might prioritise wind resistance and durability, while renovation works could focus on dust containment and visibility. Urban construction sites often need materials with enhanced safety features to protect pedestrians.

Consider these practical aspects:

- Project duration and material reusability

- Cost-effectiveness versus required performance

- Installation and maintenance requirements

- Storage and handling capabilities

A thorough assessment of these factors helps ensure your chosen scaffold material meets both immediate project needs and long-term safety standards.

What Are Some Real-Life Examples of Effective Use of Scaffold Mesh and Netting?

The Sydney Opera House renovation project in 2021 demonstrated the exceptional versatility of scaffold mesh. The iconic building required extensive exterior work while maintaining its visual appeal for tourists. The installation of white scaffold mesh provided essential debris containment and matched the building’s aesthetic, allowing tourism activities to continue throughout the construction phase.

High-Rise Applications

- The Q1 Building in Gold Coast used high-strength scaffold netting during its glass facade replacement

- The netting system caught tools and materials while allowing natural light to penetrate

- Workers reported improved safety confidence, leading to increased productivity

Infrastructure Projects

- Brisbane’s Story Bridge maintenance project utilised green scaffold mesh

- The mesh colour choice reduced visual impact on surrounding areas

- Debris containment prevented materials from falling into the Brisbane River

- Local businesses reported minimal disruption to their operations

Residential Developments

- Melbourne’s Docklands apartment complex renovation used scaffold mesh with 90% coverage

- Protected neighbouring properties from dust and debris

- Reduced noise pollution by 40%

- Maintained resident privacy during construction

Heritage Building Restoration

- Perth Town Hall restoration employed custom-fitted scaffold netting

- The breathable material protected delicate stonework from weather damage

- Allowed heritage experts to monitor the building’s condition throughout repairs

- Achieved heritage conservation requirements while ensuring worker safety

These real-world applications showcase how scaffold mesh and netting adapt to diverse construction challenges, delivering practical solutions across different project scales and requirements.

Conclusion

Your selection must align with:

- Project-specific requirements

- Local weather conditions

- Duration of construction

- Safety regulations

- Budget constraints

Remember: investing in the right scaffolding material isn’t just about compliance – it’s about creating a secure, productive work environment that protects both your workers and the public. Make your choice based on thorough assessment of your project needs and industry standards to ensure optimal site safety and project success.